Lifetime Warranty: Guaranteed for life not to rust, peel or chip. No quibble guarantee.

Guaranteed for life not to rust, peel or chip.

Set of Forged Replacement Wheel Tuner Nuts. Available in sets of 8, 10, 12, 16, 20, or 24 - choose using the dropdown box above.

Tuner Nuts have an internal spline into which a special tool is inserted, which then allows you to use a wheel brace as usual, instead of the usual hex head. They are designed for wheels with a smaller counterbore, which therefore don't have room for a socket when used with normal nuts. This usually only applies to aftermarket alloy wheels. Everything you need will be supplied: the locking key, tuner key, and sleeve.

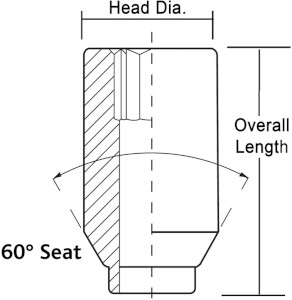

Specifications

- Thread Size (T): M12x1.25

- Overall Length (L): 37mm

- Tuner Head Outer Diameter: 20mm

- Hex Size: 17/19mm

- Seating: 60 Degree

- Finish: Black Zinc

Spot The Difference

A fresh set of wheel bolts can make a big difference to the appearance of your wheels. Old bolts which have gone rusty, or have cracked or peeling paint, stand out and spoil the look of your otherwise pristine alloy wheels. Replacing them with a new set of high quality Forged bolts and locking bolts not only secures your wheels and keeps you safe, but with their hard wearing protective finish also adds a finishing touch to your car. And with a lifetime guarantee, you know it will last.

Before - Porsche Cayman alloy wheels with old, rusty bolts

After - alloy wheels with new Forged bolts and locking bolts

How are they made?

Our Forged wheel nuts and bolts are made to the highest specification at state of the art facilities in Italy.

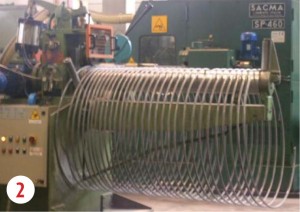

Raw material is prepared for cold forging and turning. Inspected and checked before being processed.

Beginning of the bolt production process - raw material being prepared for the forging machine.

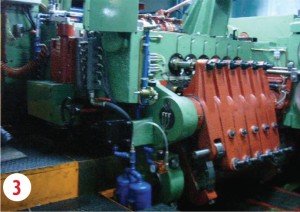

State of the art cold forging machine which produces the wheel bolts.

Turning machines for the production of wheel nuts and various components.

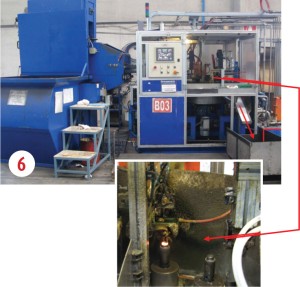

Heat treatment plants for hardening the lock body and components.

Induction hardening equipment to maximise the lock head strength and resistance.

Automated thread rolling machine for precision threads.

State of the art plating process. A variety of finishes are available.

Dehydrogenation process.

On site metallurgy testing facility for quality control.