Lifetime Warranty: Guaranteed for life not to rust, peel or chip. No quibble guarantee.

Guaranteed for life not to rust, peel or chip.

Introducing Forged Locking Wheel Bolt Packages for a Audi 200. The package is a complete kit to transform the look of your Original Equipment Alloy Wheels.

Lifetime Warranty: Guaranteed for life not to rust, peel or chip. No quibble guarantee.

Clean unmarked Alloy Wheels transform any car. However scruffy nuts, bolts, and locking bolts look even worse when the alloy wheels are perfect. The Forged kit not only solves this issue, but it ensures the safety of your car by ensuring you have the best, original equipment quality bolts and the best and most secure locking bolts on the market. Finally, these will all stay looking pristine for years to come as the Italian manufacturers ensure longevity by their rigorous, well tried and tested manufacturing processes.

The plating process includes several layers of nickel and one layer of microporous chrome producing a superior finish while protecting against rust. Every lock is through-hardened and tempered. Manufactured in Italy to meet or exceed OEM standards.

Due to the unique key patterns, the pattern shown in images may differ from the pattern on the locks you receive.

The Forged kit includes a set of ultimate quality and ultimate security Thatcham Approved Locking Wheel Bolts in Black or Silver finish (select using dropdown box above), a set of Black Caps to cover and protect the locking wheel bolts, a specifically designed puller to remove the caps that can be kept securely with the locking bolt ‘key’ in a purpose made case, and a wheel alignment tool to transform the task of lining up, supporting, and fitting the Original Equipment Alloy Wheel to your Audi.

What's Included?

- Set of Thatcham Approved Silver or Black Locking Wheel Bolts for Original Equipment Alloy Wheels

- Set of protective and decorative Grey Locking Wheel Bolt Caps

- Specifically designed Puller to remove the Locking Bolt Caps

- High Tensile Locking 'Key' for the Locking Wheel Bolts

- Purpose Case for Locking Bolt Key and Puller

- Self-adhesive 'Key' Number Sticker

- Wheel Alignment Tool for easy fitting of your Original Equipment Alloy Wheels

Spot The Difference

A fresh set of wheel bolts can make a big difference to the appearance of your wheels. Old bolts which have gone rusty, or have cracked or peeling paint, stand out and spoil the look of your otherwise pristine alloy wheels. Replacing them with a new set of high quality Forged bolts and locking bolts not only secures your wheels and keeps you safe, but with their hard wearing protective finish also adds a finishing touch to your car. And with a lifetime guarantee, you know it will last.

Before - Porsche Cayman alloy wheels with old, rusty bolts

After - alloy wheels with new Forged bolts and locking bolts

Will these definitely fit my car?

This complete set is designed specifically to fit your car. Several factors are taken into consideration including wheel bolt threads, pitch, thickness, seating and length: the strength of the material in the first instance to be able to take and exceed the torque settings required and the hex size to fit the original equipment wheel brace supplied with the car. The locking wheel bolts similarly need to be of the correct specification to be the perfect fit for the Original Equipment Alloy Wheels. Not only the fit but the security levels and operational levels of these locking wheel bolts need to be perfect and they are.This Forged Locking Wheel Bolt Package has been developed to fit your vehicle. As long as you have selected the correct vehicle you can rest assured that it will fit perfectly. If you're not sure which kit is suitable for your vehicle, please feel free to contact us and we will be happy to help.

Technical specifications

- Thread: M14x1.5 (27mm long)

- Overall bolt length: 47mm

- Seating: R13 radius

- Hex size: 17mm

- Locking Key Outer Diameter: 29mm

Note: this is for vehicles which use 5 bolts per wheel.

Each Forged Locking Wheel Bolt Package is engineered for a specific vehicle fitment. The original equipment wheel size, stud pattern, seatings, hex are all taken into consideration.

The thread diameter refers to the diameter of the threaded section of the stud, measured across the shank at the outer edges of the thread e.g. 12mm. The thread pitch is the number derived at when dividing the number of threads in 10mm into 10 e.g. 8 threads along 10mm has a pitch of 1.25.

Note: It is extremely important that the nut or bolt seat properly in the wheel bolt hole. The vast majority of aftermarket wheels use a tapered nut or bolt (usually with a 60 degree taper). Some wheels use a radius taper bolt/nut. Our trained team will ensure correct fitment for you.

Locking wheel nuts/bolts are an an essential accessory to help to keep your new wheels safe from theft, an available to upgrade for all Alloy Wheels that we sell.

They act as a substitute for one of the wheel bolts/nuts per wheel, and a key (supplied) is used to tighten or loosen the locking wheel bolt/nut. Acting as a security feature, you need the dedicated key to remove the wheels from the vehicle.

In a set you receive 4 locking nuts or bolts, whichever is relevant to your cars fitment, and a key to lock them on to the car. It is important to make a note of the key number (supplied with the set) in case you require a replacement key in the future. If you do not do this and lose the key then it will be very difficult to remove the locking wheel nuts/bolts.

How are they made?

Our Forged wheel nuts and bolts are made to the highest specification at state of the art facilities in Italy.

Raw material is prepared for cold forging and turning. Inspected and checked before being processed.

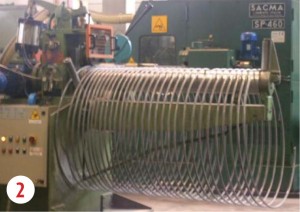

Beginning of the bolt production process - raw material being prepared for the forging machine.

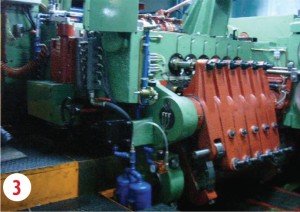

State of the art cold forging machine which produces the wheel bolts.

Turning machines for the production of wheel nuts and various components.

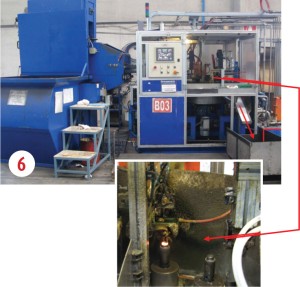

Heat treatment plants for hardening the lock body and components.

Induction hardening equipment to maximise the lock head strength and resistance.

Automated thread rolling machine for precision threads.

State of the art plating process. A variety of finishes are available.

Dehydrogenation process.

On site metallurgy testing facility for quality control.